In recent years, China National Chemical Engineering Co. Ltd. (hereinafter referred to as "CNCEC") actively participates in the construction of “The Belt and Road”, which was initiated by China, and carried out cooperation and exchanges with countries along the route.

Hualu Engineering & Technology Co., Ltd. (hereinafter referred to as “Hualu”) has been closely following the deployment strategy of CNCEC. In June 2018, with the care and support of CNCEC, Hualu signed the EPC contract of the MCR Revamp Project with PARCO, who is the most important partners in Pakistan in addition to NRL.

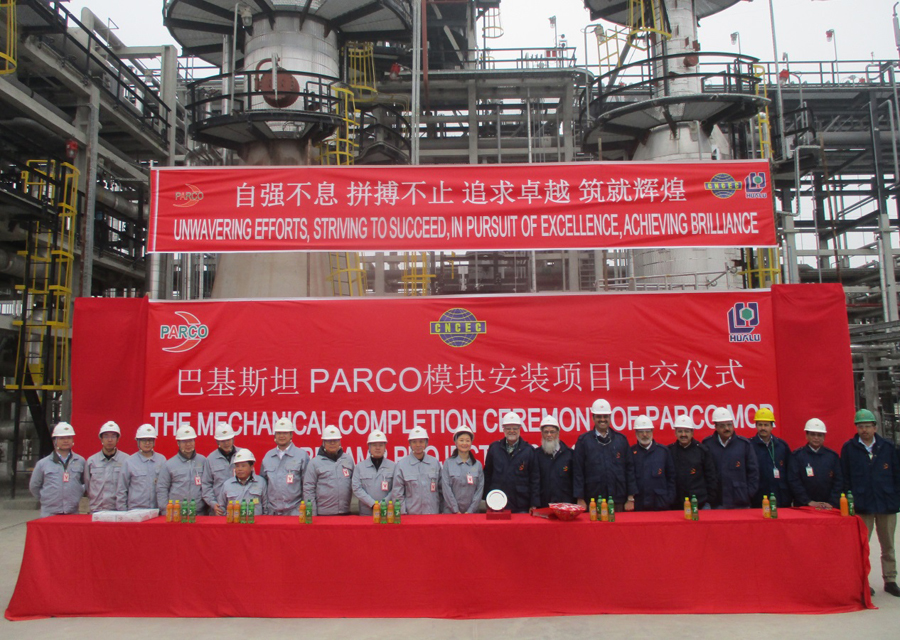

On December 30, 2019 (local time), on the project site of Multan, Punjab, Pakistan, Hualu and PARCO, successfully carried out the MC ceremony of the MCR Revamp Project. This was the most important milestone of the project and meant that the main construction activities finished and entered into the commissioning stage, meanwhile, it also showed Hualu’s strong capability on Modular erection and enhanced the confidence of the expansion overseas market.

MCR Revamp Project is another refinery project in Pakistan Market, the scope of this project mainly include PSA, PENEX, OSBL and Hualu as an EPCC Contractor, mainly responsible for field engineering, design review, equipment and material procurements, transportation, installation and construction, pre-commissioning and assistance to start-up.

In order to meet the growing production requirement in the Pakistani market, and to reduce the pollution and improve environment, this project will increase quantity and quality of the gasoline and diesel.

This project is the first overseas Modular erection project which consists of 35 modules. PENEX Unit is main Modular unit and composed of 32 modules and few off-module devices. It has strictly requirements and limitation on transportation. In order to meet the requirements, the module shall be cut with the axis and layer of the frame; the longest side is limited at about 30m, the second longest side is at about 20m, and the total weight shall less than 50t. Meanwhile, to avoid damage during the transportation, the materials and equipment such as pipes around steel structures, cable trays, towers and platforms of column are all delivered as prefabricated parts. All anti-corrosion and insulation of pipes shall be completed before placement. Insulation of pipes between modules shall be completed on site. During the transportation, the pipes nitrogen seal protection is required.

On January 2, 2019, the lifting ceremony of the PENEX modules was launched, and the lifting of the first module M16-A was completed in the meantime. The last module of PENEX was lifted on January 20, 2019. Only 19 days were taken in all lifting activities This construction speed not only exceeded the expectations of the Owner but also the licenser. They were all amazed by such "Chinese speed".

One minute on the stage, ten years of practice off the stage. In order to complete the lifting of the modules quickly and smoothly within 19 days, the project team has been preparing for lifting since October 2018.The project team started from the analysis and optimization of design rationality and the feasibility study of transportation and installation, and in combination with characteristics of the module, rotation angle, position of gravity center and other factors, and finally successfully completed the lifting and installation of each module. In this process, the project team has carried out scientific research and rigorous demonstration at every step to strive for excellence. One of our engineer said, "After countless hot summer days and winter days, and facing the severe challenges brought by the turbulent situation, we strive to overcome the differences in management concepts, thinking modes, operation systems, etc., and always insist on completing the project with high quality."

During the preparation process, the Project team overcomes difficulties without any prior experience to learn from, tries to eliminate hidden dangers, and makes all the effort to prepare for lifting through fine management. Compared with single equipment, the center of gravity of the module may is the seriously problem. The project team specifically checked the balance beam against the drawings for this problem. During the modules construction, the upper and lower modules need to be fixed with bolts. Therefore, the project team prefabricated the scaffolding in advance to ensure the smooth installation of the upper module. For the heavy equipment such as towers and reactors, which are difficult to prefabricate, project team conducted adequate investigations, repeatedly communicated with the Owner and other parties, and planned scientific and reasonable equipment lifting sequence in advance, which was laying a good foundation for subsequent lifting.

PARCO MCR Project contains revamp activities with existing plant, a large amount of installation and tie-in work needs to be completed within 45 days during the shut-down and overhaul. Modular construction makes this almost impossible task possible. With the modular process design, each process unit has been modularly designed and constructed to connect different main modules. The installation proportion of the electrical instrument plant is further improved, and the equipment and piping layout is more compact, which reduces the area of production equipment and effectively saves land resources.

Modular construction is mainly carried out in the precast yard with better installation conditions and higher labor efficiency. With modularization, the product has high precision and stable performance; the overall project cost is effectively reduced, the construction period and the overall project duration are greatly shortened with higher construction quality, which is especially of great significance for overseas projects. As the development trend of future projects, modularization is an approach to implement the professional and international strategy of Hualu. Hualu will take modular construction technology as an important approach to cater for different project environment in the future.