In the past few years, China National Chemical Engineering Co., Ltd. (CNCEC) has been resolutely responding the policy of Chinese Government, making lots of efforts to participate in the construction of “One Belt And One Road” and actively carrying out extensive cooperation with One Belt And One Road countries.

Pak-Arab Refinery Limited (PARCO) is a state-owned company, which has the largest refinery in Pakistan, and operates most of oil products, white oil pipelines, and has an important domestic market share all over the Pakistan. In 2017, Mr. Liu Jiaqiang, the current General Manager of CNECE, visited PARCO headquarters in Pakistan several times and held talks on business contact and deepening cooperation between CNCEC and PARCO, which laid a solid foundation for the later cooperation between the two companies.

Hualu Engineering & Technology Co., Ltd.(HUALU)is closely following the strategic deployment of CNCEC, with the care and support of Group Company, HUALU and PARCO signed MCR REVAMP PROJECT (Package II) EPCC contract in June 2018. Meanwhile, PARCO became another important Partner in Pakistan market after National Refinery Limited.

During the project execution stage, the Deputy General Manager Mr. Wu Xiangong paid close attention to the project and coordinated the site work to resolve the problems such as human resources issue. At the same time, under the guidance and help of the International Business Department of the Group Company, the project was carried out orderly and smoothly.

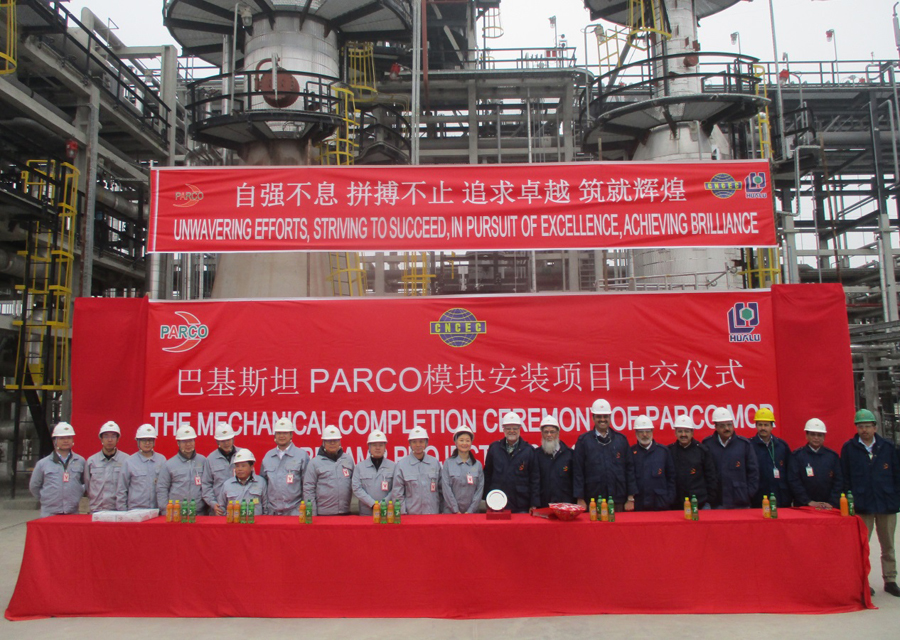

On 30th December, 2019, with the hard work of all the staff, PARCO MCR REVAMP PROJECT (Package II) finally reached the Mechanical Completion condition. Everyone's face was filled with joy, and the eye-catching banner reminded us that the Mechanical Completion Ceremony was held solemnly.

Mechanical Completion is the most important milestone of the overall project and meanwhile, it is also the mark of the project coming into the pre-commissioning and commissioning stage. The successful of Mechanical Completion is also the very important milestone of HUALU on improving the modular engineering capability and construction technology. After this project, HUALU is more mature in modular, sconstruction, and will be taken another solid step for the promotion of overseas markets.

HUALU is executing the PARCO MCR REVAMP PROJECT (Package II) Works for developing the design, design verification, procurement and supply of Bulk Materials and Equipment, fabrication, transportation, construction, installation, erection, testing, pre-commissioning and assistance in commissioning, start-up and performance testing of all facilities of MCR Revamp Project (Package-2) including two new units PSA and PENEX, as well as OSBL works including Isomerate Storage tank, Local Crude Day Tanks, transfer pumps, Substation Building (SS-11), Rack room, relevant OSBL piping lines.

PARCO MCR REVAMP PROJECT (Package II) is also the first overseas modular project of HUALU, which consists of total 35 modules of PSA and PENEX Plant. This project will not only increase the quality and production of gasoline and diesel to meet the increasing demand of oil consumption in Pakistan market, but also effectively reduce exhaust pollution and improving the environment.

The PENEX Plant consists of 32 modules (In-module) and a few number of equipment and bulk material of outside the modules (off-module). To satisfied the high requirement of the Module transportation, the module shall be segmented to pieces along with the axis and layer of the structure framework, the length shall be limited into 20~30 meters, and width and height to 4~5.5 meter, in addition, the total weight shall be less than 50 ton. Meanwhile, in order to avoid inter-damage during the transportation, the pipes support and surrounding steel structure, cable tray ties, ultra-high equipment and the attached platform and other bulk materials shall be separated in off-module. All the pipelines in-modules shall be pre-installed to finish the painting, marking and insulation work, whereas the insulation between in-module and off-module shall be completed on site. After pre-fabricated the in-module parts, all of the in-module pipelines shall be sealed and nitrogen-filled to avoid corrosion during the transportation.

A ceremony marking the start of module lifting was held on 2nd Jan 2019, and lifting of the first PENEX module M16-A was completed on the same day. On 20th Jan 2019, the last PENX module was lifted to its due location meaning that it only took 19 days for the entire module lifting. The client was shocked and impressed by the marvellous ‘Chinese Speed’ which also won a highly praise from site representative of licensor. As the old saying goes, one minute on stage is supported by hard work of decade. Project team started preparation for module lifting work early in October 2018 to ensure a rapid and smooth lifting within 19 days. From 6th Oct 2018, project team had been inspecting the modules for all aspects such as module appearance, equipment integrity within modules, entirety of loose materials etc. During the inspection, project team checked all details based on design drawings. Damage, deformation and missing parts of modules during the transportation was all found out timely and solved accordingly.

During the module lifting, HUALU carried out a series of actions on construction safety and quality assurance, finally achieving the perfect realization of ‘HUALU scheme’.

Project team began with rationality analysis and optimization of detailed design, and went deeper with feasibility research of transportation and installation, then combined module features, lifting rotation angle and gravity center location, and at last ended with a successful module lifting and installation. Throughout the whole period, project team was researching, demonstrating and improving. As is described by our site engineer: “striving from days to nights, suffering from burning sun and freezing cold, facing challenge of tense regional situation, overcoming differences of management philosophy and operation system, we stuck to a really high quality level and achieved mechanical completion.”

Without previous experience for reference, project team paid great efforts on detailed management to avoid potential risks and got well prepared for module lifting.

Compared with individual equipment, there might be some deviation of gravity center for the module. Focusing on this issue, project team carried out strict verification equalizing beam against related drawings.

Bolts would be used to fix vertically adjacent modules. Project team fabricated scaffoldings in advance, which ensured the easier installation of upper modules.

As for some columns and reactors which were hard to pre-fabricate, project team conducted a deep investigation and discussed with client back and forth. A proper lifting schedule for heavy equipment was carefully made and successfully executed.

PARCO MCR REVAMP PROJECT is based on the upgradation of existing plant. A lot of installation and tie-in need to be completed within a 45 days Turn-Around, which is a nearly impossible mission. However, modularized engineering and construction provided possibility to this task. Each process unit was designed and fabricated as individual modules, which were further assembled to generate a whole plant. Prefabrication ratio of electric and instrument devices was further improved. Equipment and piping layout was also compacted, which could decrease floor area and economize land resources.

Looking back on the tough journey of the project, we can see that the achievement is based on the concerted effort of Chinese and Pakistani. From prospecting and kickoff to100-day-expediting, from multi-discipline site support to senior management communication and coordination, HUALU and PARCO were always walking shoulder by shoulder and devoting maximum sincerity to face and overcome any difficulty.

The General Manager of HUALU, Mr. Kang Jianbin visted PARCO headquarters to meet PARCO MCR General Manager Mr. Imran, the project manager Mr. Yasin. On the senior management meeting, both side communicated, coordinated and reached agreements, which provided great support for the execution of project.

The General Manager of PARCO MCR Mr. Imran, CNCEC Pakistan representative Mr. Li Jiulong, HUALU deputy general manager Ms. Yuan Na, SCC deputy general manager Mr. Liu Xianyue took part in mechanical completion ceremony. Mr. Imran expressed warm congratulations to the successful mechanical completion of the project. In his speech, Mr. Imran highly praised and thanked for the hard work of project team, showing willingness to deepen the relationship with HUALU and looking forward to further cooperation. Ms. Yuan Na replied with gratefulness for the fully trust and great support from PARCO during the project. Ms. Yuan Na hoped that both sides can strengthen communication, deepen mutual trust and step together to a brighter future.

At the end of the ceremony, Ms. Yuan Na presented memorial gifts to Mr. Imran and M/s PARCO, wished that friendship between China and Pakistan will long live and prosper with further project construction and continuous cooperation.

Most of the work of modular construction is completed in the prefabrication factory with better installation conditions and higher labor efficiency. After modularization, it has higher precision and quality, more stable performance, and will be effectively reduced the project cost, and greatly shortened the construction period and the overall project schedule, which has the great significance for the project, especially for overseas. Based on the advantages and characteristics, modularization, as a future project development trend, will become an important methodology to realize the HUALU’s strategy of professional and international. Next, HUALU will take modular technology as an important method to promote high-quality development, continue to increase the investment of related technology, incessant to enhance the core competitiveness, and will be a strongly contribution for HUALU to become a leading technology, engineering, management excellence, diversified development of the international first-class engineering company.